Design Service

At Venom Control Systems we have many years experience in the design and manufacture of embedded control systems.

Most of our designs are built around our family of industrial microcontrollers (VM2), and we also do general electronic and software design.

Some of our designs are shown below, selected from the many consultancy projects we have undertaken.

Hardware

- Digital electronics

- ARM and STM32

- Analogue electronics

- Measurement and control systems

- Physics

- Mechanical engineering

- Electronic assembly

- Production engineering

- Production testing

Custom Designs

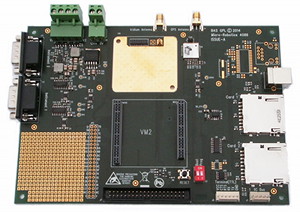

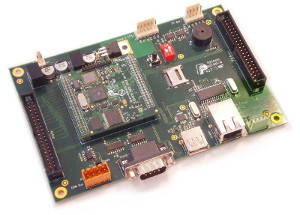

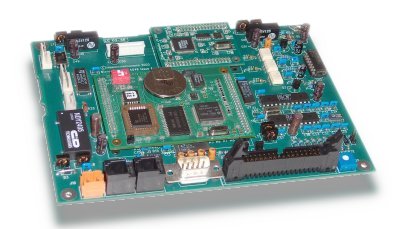

New Logger For BAS

The British Antarctic Survey commissioned our engineers to produce a general purpose data logger that builds on technology developed for the BAS Radar Controller.

Based on the VM2 microcontroller, the logger has dual redundant memory cards, an Iridium satellite modem, a GPS module and an I2C Bus as standard.

New features are two instrument channels, each consisting of a power-switchable RSR232 serial port and associated 12VDC power supply, a large number of general purpose I/O pins and a prototyping area. An Ethernet interface allows it to be configured using a web browser. The low power sleep mode is critical in extending battery life over the Antarctic winter.

Technologies

- File systems on two SD cards for redundancy

- Ethernet

- Iridium satellite modem

- GPS

- Ethernet for Web server

- Low power standby modes

- Ultra Low power, low noise switching power supply

Software

Software was written by the customer in Venom2.

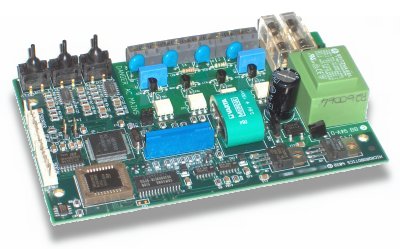

4A Switch Mode Power Supply with 5µA Iq

Designed for the British Antarctic Survey, this is a switch mode power supply for instruments powered from a 12V battery. The 5µA quiescent current means the power supply can be left on continuously for months without undue drain on the battery, removing the need for complex power switching. The efficiency of better than 90% is remarkable, though not critical in this application.

Technologies

- Low noise Switch Mode Power Supply design

Swimming Pool Plant Room Controller (Mk 3)

This pair of boards controls and monitors swimming pool plant.

It senses chemical levels, flow rates, temperature,

etc. and operates dosing pumps and heaters to maintain set point levels.

The controller is based on our VM2D

module, which drives a full colour VGA touchscreen display.

Software

Application code

written in Venom2 by Micro-Robotics.

The HMI is based on our GUI Framework.

Technologies

- VGA LCD & Touchscreen

- USB and MicroSD Card file systems

- Ethernet

- CAN Bus

- Fully isolated analogue inputs

- Pulse counting inputs

- Thermistor inputs

- Relay outputs

Ultra-High Impedance Buffer Amplifier

Probe-head buffer amplifier to signal-condition pH and Redox probes for plant room control system above. Copes with source impedances in the Gig-Ohm range.

Technologies

- Ultra-high impedance circuit techniques.

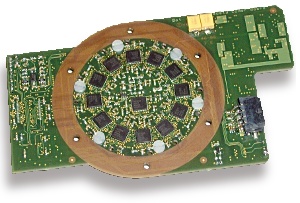

Precision Complex-Impedance Instrument

This device measures complex impedance (i.e. real and imaginary parts) to better than 0.01%. It can read twelve channels concurrently at up to 100KHz.

Technologies

- Fast 16-bit ADCs

- High speed, high precision analogue design

- DDS (Direct Digital Synthesis) – of drive frequency

- ARM Cortex-M3 Microcontroller (STM32)

Software

Embedded C: Full driver software, including Fourier techniques and complex analysis, written by Micro-Robotics

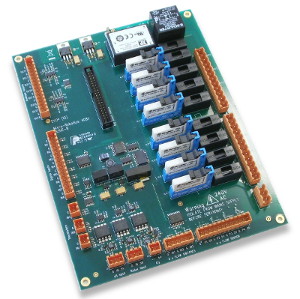

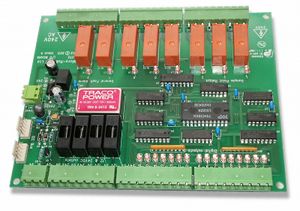

Gas Sensor Interface

This board controls an array of gas sensors to monitor air quality.

Technologies

- Relays and digital outputs

- 4-20mA 18 bit analogue input with over-current protection

- All I/O connected via I2C Bus

- VM2 controller on standard application board (not shown)

- Colour Graphics display (not shown)

Software

Venom2 code written by customer.

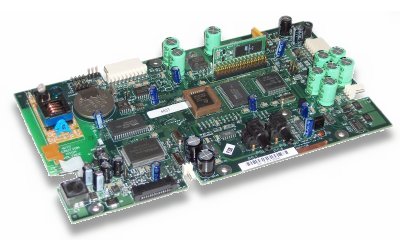

Graphical User Interface Controller: Medical

This unit sits at the heart of several different high-end medical instruments. It was commissioned because embedded PCs proved too slow and unreliable.

Technologies

- CAN Bus

- SD Memory Card

- LCD Touch Screen display

- Very low power consumption

Software

Embedded C: Comprehensive self-test suite written by Micro-Robotics; application code written by customer.

Vacuum Pump Controller: Medical

Controls vacuum applied to an airtight dressing to reduce wound healing times. Has saved many lives. Mains or battery powered.

Very high volume product: 24,000 units manufactured by us as of December 2010.

Technologies

- Pressure sensors

- Pump Drive

- Graphical user interface

- Touch Screen

- On board high capacity serial flash

Software

Embedded C: Self-test suite written by Micro-Robotics; application code written by customer.

Portable Vacuum Pump Controller: Medical

Portable version of the device above. Can be worn at the patient’s hip. Battery powered.

Technologies

- Pressure sensors

- Space/form-restricted design

- Innovative pump drive software for power saving

Software

Embedded C: Full application and self-test code written by Micro-Robotics.

Remote-control Visual Basic application to monitor and control units in the field over telephone line, and also update operating system: written by Micro-Robotics.

Clinical Nerve Stimulator

Delivers high voltage, low energy pulse stream to patient’s skin and monitors response. Engineered for size, cost, user interface and power consumption.

Technologies

- High voltage pulse generation and measurement

- Small form factor graphics LCD

- Very low power consumption

- Ergonomic handheld design

- Pay-as-you-go credit scheme with encrypted recharge facility

Software

Embedded C: Written by Micro-Robotics.

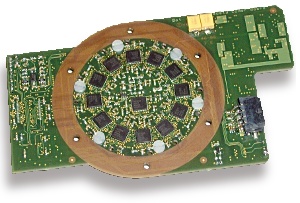

Down-Hole Data Logger

Measures physical parameters several kilometers down a borehole, transmitting them to the surface over a current loop

serial link. Based on our standard VM1 controller, seen here mounted in the centre of the main board.

This was a quick turn-around design to meet ship sailing deadline: six weeks from contact to working prototypes, further three weeks to production units.

Technologies

- Current Loop data transmission

Software

Venom Application code written by customer.

Concrete Mixing Plant Controller

Controls weighing and mixing of ingredients in concrete production plant. Based around the VM1 single board microcontroller.

Technologies

- Loadcell bridge input

- Graphical user interface

- Opto-isolated 4-20mA output

Pneumatic Mattress Controller: Medical

High volume, low cost controller for therapeutic mattress. Alternating inflation of mattress cells to reduce risk of bedsores. 230/115 VAC Mains powered.

Technologies

- Pressure sensors

- Opto TRIACs

Software

Embedded C: Full application and self-test code written by Micro-Robotics.